PEB Warehouse Construction Timeline: From Design to Project Handover

One of the biggest reasons developers and logistics companies prefer PEB (Pre-Engineered Building) warehouses is speed.

Compared to RCC construction, a well-planned PEB warehouse can be designed, fabricated, erected, and commissioned in almost half the time—without compromising structural performance.

This blog explains the step-by-step PEB warehouse construction timeline, from an EPC execution perspective, so you know what happens when, how long it takes, and where delays usually occur.

Overall PEB Warehouse Timeline (Typical)

For a standard single-storey PEB warehouse:

- Total duration: 3 to 4 months

- Fast-track projects: As low as 10–12 weeks

- Large or complex warehouses: 4 to 5 months

Timelines vary based on size, height, crane requirements, approvals, and site readiness.

Stage 1: Concept Planning & Feasibility (1–2 Weeks)

This stage sets the foundation for the entire project.

Key activities include:

- Understanding warehouse usage (storage, logistics, manufacturing)

- Finalizing clear height, bay spacing, and expansion needs

- Selecting structure type (PEB only or hybrid)

- Preliminary cost and timeline estimation

Mistakes at this stage almost always lead to delays later.

Stage 2: Engineering & Authority Drawings (2–3 Weeks)

Once the concept is frozen, detailed engineering begins.

This stage includes:

- Structural design of PEB frames and foundations

- Anchor bolt drawings

- GA drawings for approvals

- Fire safety and statutory coordination (where required)

💡 EPC advantage: Engineering is done with fabrication and erection in mind, avoiding redesign later.

Stage 3: Foundation & Civil Works (3–4 Weeks)

Civil works usually start in parallel with steel fabrication.

Typical activities:

- Site leveling and excavation

- RCC foundations and pedestals

- Anchor bolt installation

- Plinth beams and floor sub-base

📌 Accuracy of anchor bolts is critical—errors here can delay erection.

Stage 4: PEB Fabrication (4–6 Weeks – Parallel Activity)

While civil works are ongoing, steel fabrication starts at the factory.

Fabrication includes:

- Primary frames (columns, rafters)

- Secondary members (purlins, girts)

- Bracing systems

- Shop primer or paint

Because this happens off-site, weather and site conditions do not affect progress.

Stage 5: Steel Erection on Site (2–3 Weeks)

Once foundations are ready, steel erection begins.

Activities include:

- Erection of primary frames

- Installation of secondary members

- Roof bracing and alignment

- Structural tightening and leveling

PEB erection is fast because components are pre-engineered and bolt-connected.

Stage 6: Roofing, Cladding & Accessories (2–3 Weeks)

After the structure is stable:

- Roof sheets are installed

- Wall cladding is fixed

- Skylights, ridge vents, louvers added

- Gutters and downpipes completed

At this stage, the warehouse becomes weather-tight.

Stage 7: Industrial Flooring & External Works (2–4 Weeks)

While roofing and cladding continue, internal and external works proceed.

Typical scope:

- Industrial flooring (VDF / FM2 / FM3)

- Dock levellers and shutters

- External roads and drainage

- Boundary works (if included)

Floor curing time must be respected to avoid cracks and surface failures.

Stage 8: Fire Safety, MEP & Utilities (2–3 Weeks)

Depending on warehouse use:

- Firefighting systems installed

- Electrical systems and lighting

- Ventilation and basic utilities

- Testing and commissioning

Early coordination between structure and services avoids clashes and rework.

Stage 9: Final Inspection & Handover (1 Week)

Final stage includes:

- Structural inspection

- Fire and safety compliance checks

- Snag clearance

- Documentation and handover

Once completed, the warehouse is ready for racking, automation, or tenant fit-out.

Timeline Comparison: PEB vs RCC Warehouse

- PEB Warehouse: 3–4 months

- Steel Hybrid Warehouse: 4–5 months

- RCC Warehouse: 7–10 months

⏱ Time saved = earlier rental income or faster operations.

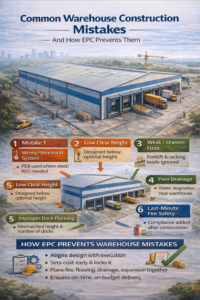

Common Reasons for PEB Timeline Delays

- Late design changes

- Poor coordination between civil and steel works

- Incorrect anchor bolt placement

- Delayed authority approvals

- Flooring scope not finalized early

Most of these are planning issues, not execution issues.

How EPC Ensures Faster PEB Delivery

An EPC-led PEB project:

- Runs design, fabrication, and civil works in parallel

- Locks specifications early

- Coordinates all vendors under one responsibility

- Minimizes idle time between stages

Well-managed EPC projects often save 20–30% time compared to fragmented contracting.

Final Thoughts

A PEB warehouse is not just fast by design—it is fast only when planned and executed correctly.

The real advantage of PEB lies in:

- Parallel execution

- Factory-controlled fabrication

- EPC-driven coordination

Planning a PEB Warehouse?

Before committing to timelines, a PEB project schedule review should confirm:

- Design freeze milestones

- Civil vs fabrication overlap

- Erection readiness

- Flooring and fire coordination

A realistic, well-sequenced timeline is the difference between a fast project and a delayed one—even with PEB.