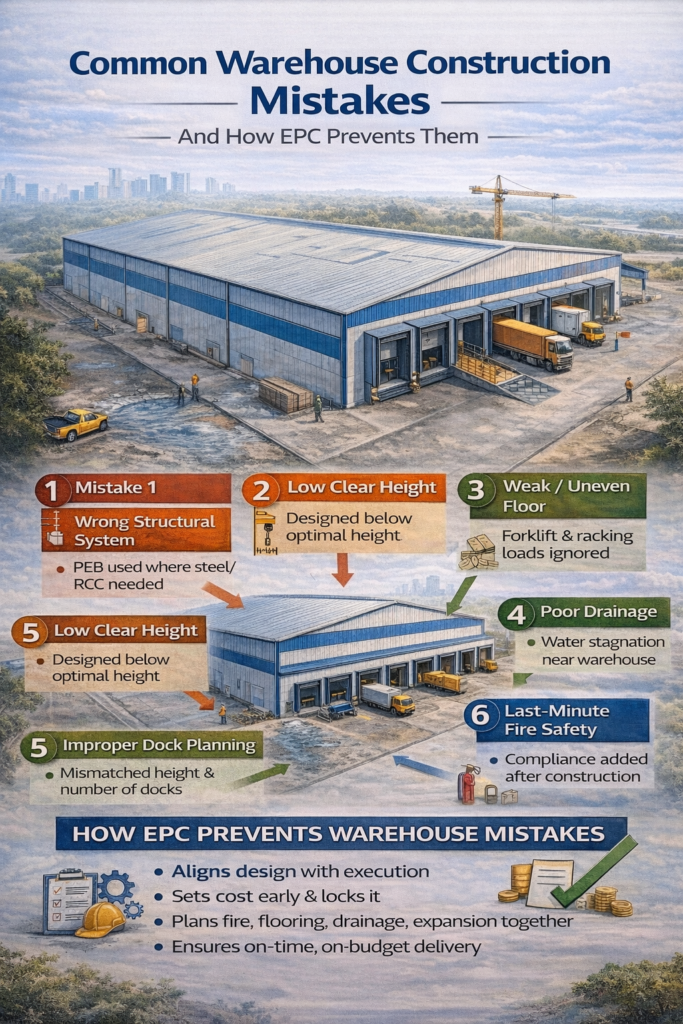

Common Warehouse Construction Mistakes (and How EPC Prevents Them)

Most warehouse projects don’t fail because of poor workmanship.

They fail because of wrong decisions made at the planning stage.

A warehouse looks simple—but it is a highly functional industrial asset. Small mistakes in structure selection, floor design, drainage, or fire planning can lead to operational bottlenecks, safety risks, and expensive retrofits.

This blog highlights the most common warehouse construction mistakes in India and explains how an EPC-led approach helps avoid them.

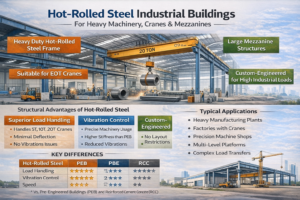

Mistake 1: Choosing the Wrong Structural System

One of the biggest mistakes is selecting PEB, RCC, or steel purely based on initial cost.

What often goes wrong:

- PEB chosen where heavy loads or cranes are required

- RCC chosen where speed and expansion matter

- No provision for mezzanines or future loads

Correct approach:

The structure must be selected based on usage, loads, height, expansion plans, and timeline, not just ₹/sq.ft.

Mistake 2: Underestimating Clear Height Requirements

Many warehouses are designed with minimum clear height to reduce cost.

This leads to:

- Inefficient racking systems

- Reduced storage capacity

- Inability to adapt to new logistics standards

Correct approach:

Clear height should be decided based on racking design, fire sprinklers, lighting, ducts, and future automation, not roof height alone.

Mistake 3: Poor Industrial Flooring Design

Flooring failures are one of the most expensive warehouse issues.

Common flooring mistakes:

- Ignoring forklift axle loads

- Not considering racking point loads

- Poor sub-base preparation

- Wrong floor flatness (FM level)

Correct approach:

Floor design must be finalized after racking and equipment planning, using proper load calculations and floor performance standards (VDF, FM2/FM3).

Mistake 4: Ignoring Drainage and External Levels

Drainage is often treated as an afterthought.

This results in:

- Water stagnation near docks

- Flooding during monsoons

- Damage to flooring and foundations

Correct approach:

Warehouse drainage should include site grading, stormwater channels, rainwater harvesting, and dock-level water control, planned from day one.

Mistake 5: No Planning for Dock Levellers & Logistics Flow

Warehouses are logistics-driven buildings, yet loading docks are frequently poorly designed.

Common problems:

- Incorrect dock height

- Insufficient number of docks

- Poor truck turning radius

- Traffic congestion inside the site

Correct approach:

Dock layout must be designed based on vehicle types, turnaround time, and operational volume, not guesswork.

Mistake 6: Fire Safety Treated as a Last-Minute Requirement

Fire compliance is often added after construction is complete.

This causes:

- Design changes

- Approval delays

- Cost escalation

- Reduced usable space

Correct approach:

Fire safety must be integrated into:

- Column spacing

- Roof height

- Sprinkler zoning

- Travel distances

- Fire tender access

Early coordination avoids redesign and authority rejections.

Mistake 7: No Provision for Future Expansion

Many warehouses are designed only for current needs.

This leads to:

- Costly shutdowns during expansion

- Structural strengthening later

- Inefficient layouts

Correct approach:

Expansion-ready design includes:

- Foundation overdesign

- Modular bay spacing

- Removable wall panels

- Spare electrical and fire capacity

Mistake 8: Fragmented Contracting (Too Many Vendors)

Managing separate consultants, PEB suppliers, civil contractors, and MEP vendors often results in:

- Coordination failures

- Scope gaps

- Blame-shifting

- Delays and rework

Correct approach:

A single EPC contractor ensures design, procurement, and execution are aligned from start to finish.

How EPC Prevents These Warehouse Mistakes

An EPC-led warehouse project:

- Aligns design with execution

- Locks cost early

- Identifies hidden risks upfront

- Plans for fire, flooring, drainage, and expansion together

- Reduces lifecycle cost, not just initial cost

Warehouses built under EPC typically deliver:

- Faster completion

- Fewer variations

- Better operational performance

Final Thoughts

A warehouse is not just a shed—it is a business-critical infrastructure asset.

Most warehouse construction mistakes are avoidable with the right planning, the right structure, and the right delivery model.

Planning a Warehouse Project?

Before finalizing drawings or vendors, a warehouse feasibility review should cover:

- Structure selection (PEB vs RCC vs steel)

- Clear height and racking compatibility

- Flooring and drainage design

- Fire safety and approvals

- Expansion readiness

Fixing mistakes on paper costs nothing.

Fixing them after construction can cost crores.