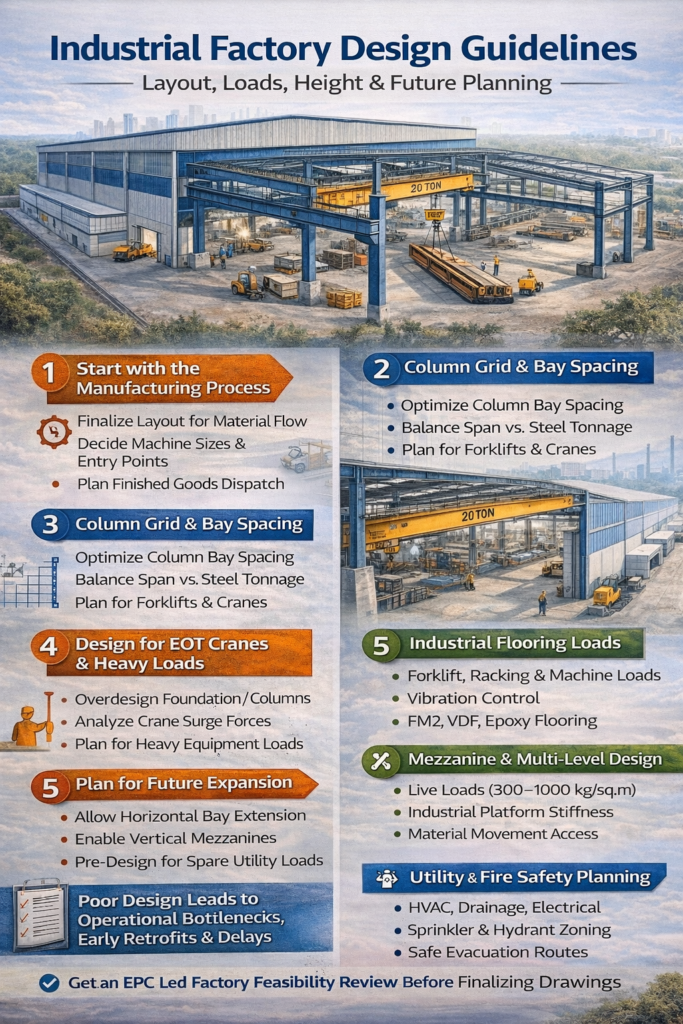

Industrial Factory Design Guidelines: Layout, Loads, Height & Planning

Designing an industrial factory is fundamentally different from designing residential or commercial buildings. A factory must support machinery, material movement, safety, utilities, and future growth—all while remaining cost-efficient and operationally smooth.

Most factory design problems do not come from construction quality. They come from wrong planning decisions taken too early and corrected too late.

This guide explains practical industrial factory design guidelines from an EPC execution perspective, focusing on performance, safety, and long-term flexibility.

Start With the Manufacturing Process

Factory design must always begin with understanding the manufacturing or operational process.

Key inputs that should be finalized before any structural design include raw material entry points, internal material flow, production sequencing, machine dimensions and weights, maintenance access, and finished goods dispatch routes.

If the process flow is inefficient, no structural system—PEB, steel, or RCC—can fix it later without costly modifications.

Column Grid and Bay Spacing Planning

Column spacing is one of the most important structural decisions in factory design. It directly affects machinery layout, vehicle movement, crane integration, and total construction cost.

Typical bay spacing ranges are:

• Light manufacturing: 8 to 10 meters

• Assembly lines and general factories: 10 to 12 meters

• Heavy industrial factories with cranes: 6 to 8 meters (load-driven)

Wider bays reduce the number of columns but increase steel tonnage and foundation loads. The correct solution balances operational efficiency with structural economy.

Clear Height and Vertical Planning

Clear height refers to the usable vertical space below roof structures, services, and equipment. It is one of the most commonly underestimated parameters in factory projects.

Indicative clear height guidelines:

• Light manufacturing: 6 to 8 meters

• Warehouses and logistics: 9 to 12 meters

• Factories with cranes: crane hook height plus 2 to 3 meters

Roof height should never be finalized without accounting for crane beams, ducts, cable trays, lighting, sprinklers, and future service additions.

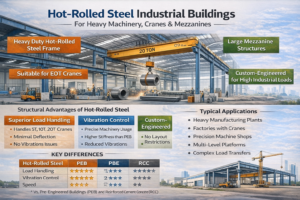

Designing for EOT Cranes and Heavy Loads

Factories with EOT cranes or heavy moving equipment require special structural planning at the foundation and column level.

Key crane design inputs include crane capacity, duty class, span, wheel loads, impact factors, and horizontal surge forces.

Even if cranes are planned “in the future,” foundations and columns must be designed for them from day one. Retrofitting crane loads later is expensive and often structurally risky.

Industrial Flooring Design Guidelines

Industrial flooring failures are among the costliest and most disruptive issues in factories.

Floor design must consider forklift axle loads, racking point loads, machine base loads, vibration sensitivity, and surface flatness requirements.

Common flooring systems include VDF floors, FM2/FM3 floors, and epoxy or PU-coated industrial floors.

Floor design should always follow finalization of racking layout and equipment planning, not precede it.

Mezzanine and Multi-Level Planning

Mezzanines are often added after operations begin, but structurally they should be planned from the initial design stage.

Design considerations include live load capacity (often 300 to 1000 kg per square meter or higher), vibration control, stair and material handling access, fire escape compliance, and headroom requirements.

Pre-planning mezzanines significantly reduces future cost and downtime.

Fire Safety and Statutory Compliance

Fire safety is not an add-on—it must be integrated into the factory design from the beginning.

Design coordination should include fire compartmentation, travel distance limits, sprinkler zoning, hydrant coverage, smoke ventilation, emergency exits, and fire tender movement.

Late-stage fire compliance changes often cause major redesigns and approval delays.

Utility and Services Planning

Factories are service-intensive buildings. Poor service planning leads to cluttered layouts and constant modifications.

Early planning should allocate space for electrical substations, cable trays, compressed air pipelines, HVAC systems, drainage lines, effluent treatment, and future service expansion.

Dedicated service corridors and vertical shafts reduce rework and maintenance issues.

Designing for Future Expansion

A well-designed factory allows growth without disruption.

Expansion-ready design includes stronger foundations, modular bay spacing, removable wall panels, spare electrical and fire capacity, and structural allowance for additional mezzanines or cranes.

Factories designed only for current needs often become bottlenecks within a few years.

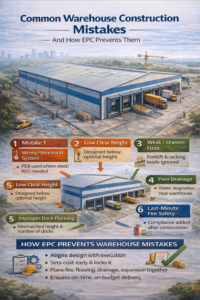

Why EPC-Led Factory Design Works Better

When factory design is handled under an EPC model, design decisions are made with execution, cost, and future use in mind.

EPC-led design reduces coordination errors, improves constructability, and optimizes cost at the planning stage. Well-executed EPC factory projects typically save 10–20 percent in lifecycle cost compared to fragmented contracting models.

Common Factory Design Mistakes to Avoid

Designing only for present machinery, ignoring future crane loads, underestimating floor loads, poor service coordination, and skipping expansion planning are the most common and expensive mistakes in industrial factories.

Final Thoughts

An industrial factory is a long-term operational asset, not just a building shell.

Correct design decisions taken early improve productivity, safety, maintenance efficiency, and scalability for decades. Once construction begins, flexibility reduces dramatically.

Planning a Factory Project?

Before freezing drawings, a factory design feasibility review should cover structural system selection, bay spacing and height optimization, crane and mezzanine readiness, cost planning, and future expansion strategy.

A few weeks of proper planning can prevent years of operational compromise.