Fire Safety & Approvals for Industrial Buildings in India

Fire safety is not a checklist item for industrial buildings.

It is a design-driven, approval-critical, and life-safety system that directly affects layout, structure, height, cost, and timelines.

Many industrial projects face delays, redesigns, or even shutdown notices—not because construction was poor, but because fire safety was treated as a last-minute requirement.

This blog explains fire safety requirements and statutory approvals for industrial buildings in India, from a practical EPC execution perspective.

Why Fire Safety Is Critical for Industrial Buildings

Industrial buildings typically have:

- Large floor areas

- High fire loads (goods, machinery, packaging)

- Limited exits if poorly planned

- Heavy vehicular movement

A fire incident can lead to:

- Loss of life

- Asset destruction

- Business interruption

- Criminal liability for owners

That’s why fire safety approvals are mandatory and non-negotiable.

Key Fire Safety Authorities in India

Fire approvals are issued by State Fire Services (varies by state and city).

Common approving authorities include:

- State Fire Department

- Local Municipal Corporation Fire Wing

- Industrial Development Authorities (MIDC, etc.)

Fire approval is usually required at:

- Provisional / building permit stage

- Final Fire NOC stage (before occupancy)

Fire Safety Codes & Standards Followed

Most industrial fire designs in India follow:

- National Building Code (NBC) of India

- Local fire service guidelines

- Factory Act requirements (where applicable)

- Insurance and risk-engineering standards

📌 Important: Fire norms vary slightly between states, but core principles remain the same.

Fire Classification of Industrial Buildings

Fire safety requirements depend on:

- Building use (warehouse, factory, manufacturing)

- Fire load density

- Building height

- Floor area

Typical classifications include:

- Low hazard

- Moderate hazard

- High hazard

Higher hazard = stricter fire systems + wider setbacks + more exits.

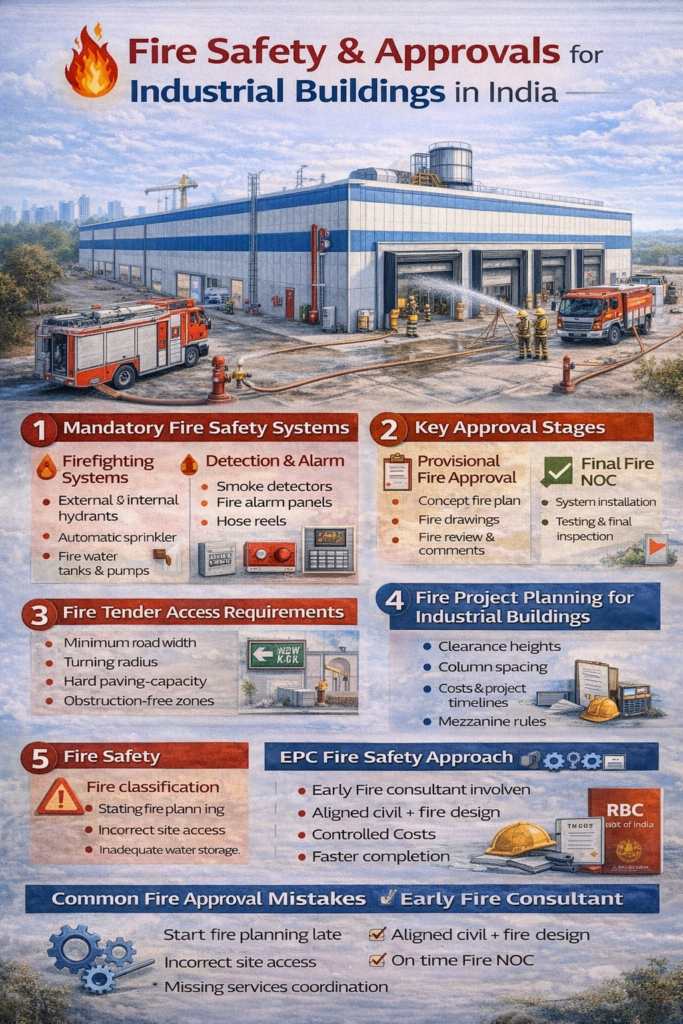

Mandatory Fire Safety Systems in Industrial Buildings

Firefighting Systems

- External and internal hydrant system

- Automatic sprinkler system (often mandatory)

- Fire water tanks and pumps

- Hose reels

Detection & Alarm

- Smoke detectors (where required)

- Manual call points

- Fire alarm panels

- Audio-visual alarms

Passive Fire Safety

- Fire-rated walls and partitions

- Fire-rated doors

- Compartmentation

- Structural fire protection (steel fireproofing if required)

Fire Tender Access & Site Planning (Most Missed Item)

One of the most common reasons for fire approval rejection is poor fire tender access.

Requirements usually include:

- Minimum driveway width around building

- Turning radius for fire tender

- Hard paving for vehicle load

- No obstruction zones

📌 This must be planned at master-planning stage, not after construction.

Exit, Travel Distance & Evacuation Planning

Fire exits must be:

- Adequately spaced

- Clearly marked

- Directly accessible

Key considerations:

- Maximum travel distance limits

- Minimum number of exits per floor

- Exit door width calculations

- Emergency lighting and signage

Ignoring these often leads to layout redesign at approval stage.

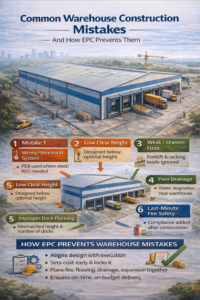

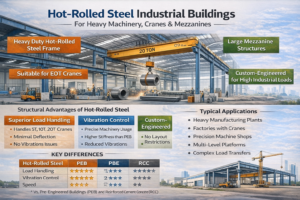

Fire Safety Impact on Building Design

Fire safety directly affects:

- Column spacing

- Clear height

- Mezzanine allowance

- Floor area efficiency

- Cost and timelines

For example:

- Adding sprinklers later may reduce usable height

- Fire walls may reduce flexibility

- Late fire shafts may clash with structure

Fire Approval Process (Typical Flow)

- Concept fire safety planning

- Submission of fire drawings

- Fire department review & comments

- Compliance revisions

- Provisional fire approval

- Installation of systems

- Testing & inspection

- Final Fire NOC

⏱ Delays usually occur when fire planning starts after structural design.

Common Fire Safety Mistakes in Industrial Projects

- Fire systems added after construction

- Inadequate water tank capacity

- No provision for future expansion

- Poor fire tender access

- Non-compliant exit distances

- Missing structural fire protection

All of these are planning failures, not execution failures.

How EPC Prevents Fire Approval Issues

In an EPC model:

- Fire consultants are involved early

- Structure, services, and fire systems are coordinated

- Fire tender access is planned with civil works

- Cost of compliance is locked early

This avoids:

- Redesign

- Approval rejection

- Cost escalation

- Project delays

Fire Safety & Expansion Planning

A good industrial building design ensures:

- Fire systems sized for future expansion

- Extra pump capacity

- Spare tank volume

- Modular zoning

Without this, future expansion often triggers fresh approvals and shutdowns.

Final Thoughts

Fire safety is not just about compliance—it is about protecting people, assets, and business continuity.

In industrial buildings, fire safety must be:

- Planned early

- Designed with structure

- Coordinated with services

- Approved before execution

Planning an Industrial Building?

Before freezing layouts or structures, a fire safety feasibility review should confirm:

- Fire classification

- Required systems

- Site access compliance

- Approval timelines

- Cost impact

Fixing fire safety on drawings costs little.

Fixing it after construction can cost months of delay and major redesign.